June 26, 2025

Guarantee Business Continuity by Strengthening Regional Supply Chain Networks

By Adán Gómez | Business Development Director at American Industries Group®

Published 01/26/2022

Though many hoped that the second year of the COVID-19 pandemic would bring more stability in industry and that companies would be better prepared for ongoing and new challenges, 2021 revealed a need for continued evolution with a focus on business continuity. With 16.7% of organizations reporting a “severe” loss of revenue due to supply chain disruptions, in addition to disruptions from other issues, including logistics and transport capacity, trade conflicts, labor shortages, and rising manufacturing costs, among others, businesses are increasingly relying on regionalizing manufacturing activity and using technology to create more reliable and efficient supply chains.

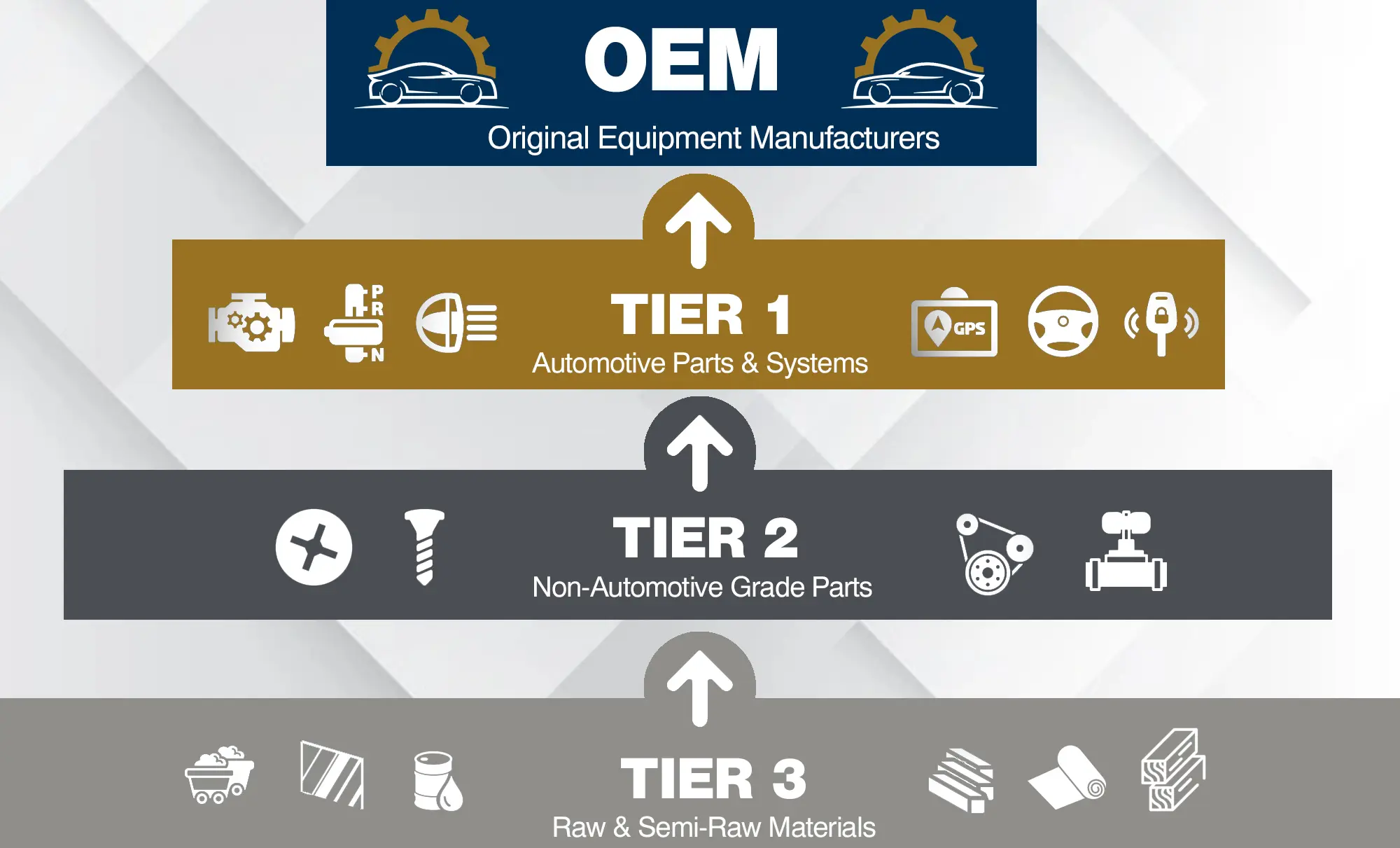

Supply chain mapping and performing due diligence are two approaches for achieving this, with a focus on tier 2 and 3 suppliers. The semiconductor shortage, which has shut down production for many of the world’s largest companies, including GM, which announced it will not resume production until mid-March 2022, revealed companies’ lack of knowledge about suppliers’ capabilities and backup suppliers to produce crucial materials.

For many businesses, the unfortunate consequences have been a temporary shutdown of production. In carrying out their due diligence, companies have found that their backup suppliers are sourcing from the same companies and regions as their main suppliers. The losses resulting from shutdowns have prompted companies to begin recording and reporting supply chain disruptions to make better decisions for business continuity. This mapping is helpful in not only ensuring the quality and reliability of products and understanding supplier networks but also in encouraging and enforcing ethical practices.

Another business continuity strategy is to create closer relationships with suppliers and invest in and reinforce regional supply networks. This increases business continuity by reducing risk and meets customer demands for local supply. The need to decrease dependency on China, move to a more regional strategy and work with highly specialized suppliers puts Mexico and its many regional industries at a competitive advantage.

One example of the opportunities it offers is in automotive manufacturing Mexico. The country’s Bajío Region provides a well-developed and mature supply chain, ensuring the availability of products needed to keep production lines open and allowing companies to better communicate with suppliers due to similar time zones and business cultures as North America. This regional industrial specialization also helps guarantee the availability of skilled and affordable labor in the face of labor shortages and mitigate logistics issues.

The automotive industry in the Bajío Region is just one example of the opportunities for international companies in Mexico. Whether you are looking to engage in nearshore or offshore manufacturing in Mexico or start up operations in Mexico, don’t hesitate to reach out to find out more about how starting up business in Mexico can help your company reduce risks and create a solid plan for business continuity in 2022 and beyond.

Supply chain mapping and performing due diligence are two approaches for achieving this, with a focus on tier 2 and 3 suppliers. The semiconductor shortage, which has shut down production for many of the world’s largest companies, including GM, which announced it will not resume production until mid-March 2022, revealed companies’ lack of knowledge about suppliers’ capabilities and backup suppliers to produce crucial materials.

For many businesses, the unfortunate consequences have been a temporary shutdown of production. In carrying out their due diligence, companies have found that their backup suppliers are sourcing from the same companies and regions as their main suppliers. The losses resulting from shutdowns have prompted companies to begin recording and reporting supply chain disruptions to make better decisions for business continuity. This mapping is helpful in not only ensuring the quality and reliability of products and understanding supplier networks but also in encouraging and enforcing ethical practices.

Another business continuity strategy is to create closer relationships with suppliers and invest in and reinforce regional supply networks. This increases business continuity by reducing risk and meets customer demands for local supply. The need to decrease dependency on China, move to a more regional strategy and work with highly specialized suppliers puts Mexico and its many regional industries at a competitive advantage.

One example of the opportunities it offers is in automotive manufacturing Mexico. The country’s Bajío Region provides a well-developed and mature supply chain, ensuring the availability of products needed to keep production lines open and allowing companies to better communicate with suppliers due to similar time zones and business cultures as North America. This regional industrial specialization also helps guarantee the availability of skilled and affordable labor in the face of labor shortages and mitigate logistics issues.

The automotive industry in the Bajío Region is just one example of the opportunities for international companies in Mexico. Whether you are looking to engage in nearshore or offshore manufacturing in Mexico or start up operations in Mexico, don’t hesitate to reach out to find out more about how starting up business in Mexico can help your company reduce risks and create a solid plan for business continuity in 2022 and beyond.

YOU MIGHT ALSO LIKE

October 10, 2022

When setting up operations in Mexico or abroad, companies must ensure they have the proper legal and corporate structure to provide certainty and minimize risk. Although […]

January 25, 2021

Faced with increasing volatility and uncertainty, business leaders are being forced to change the way they approach emerging challenges in a way that allows them to […]

February 7, 2023

On January 9-10, 2023, United States President Joe Biden and Canadian Prime Minister Justin Trudeau met with Mexican President Andrés Manuel López Obrador in Mexico City […]

June 28, 2022

Our world today is so digitalized that we can no longer imagine completing many of our everyday tasks without the help of technology. An endless number […]

July 24, 2024

Mexico has emerged as a significant hub for manufacturing, attracting numerous US and international companies looking to capitalize on its competitive advantages. The country’s proximity to […]

March 23, 2022

In today’s world filled with distractions and endless to-do lists, at American Industries, we understand that your most precious asset is time. As such, for companies […]