Operating in Mexico: How Much Will it Cost?

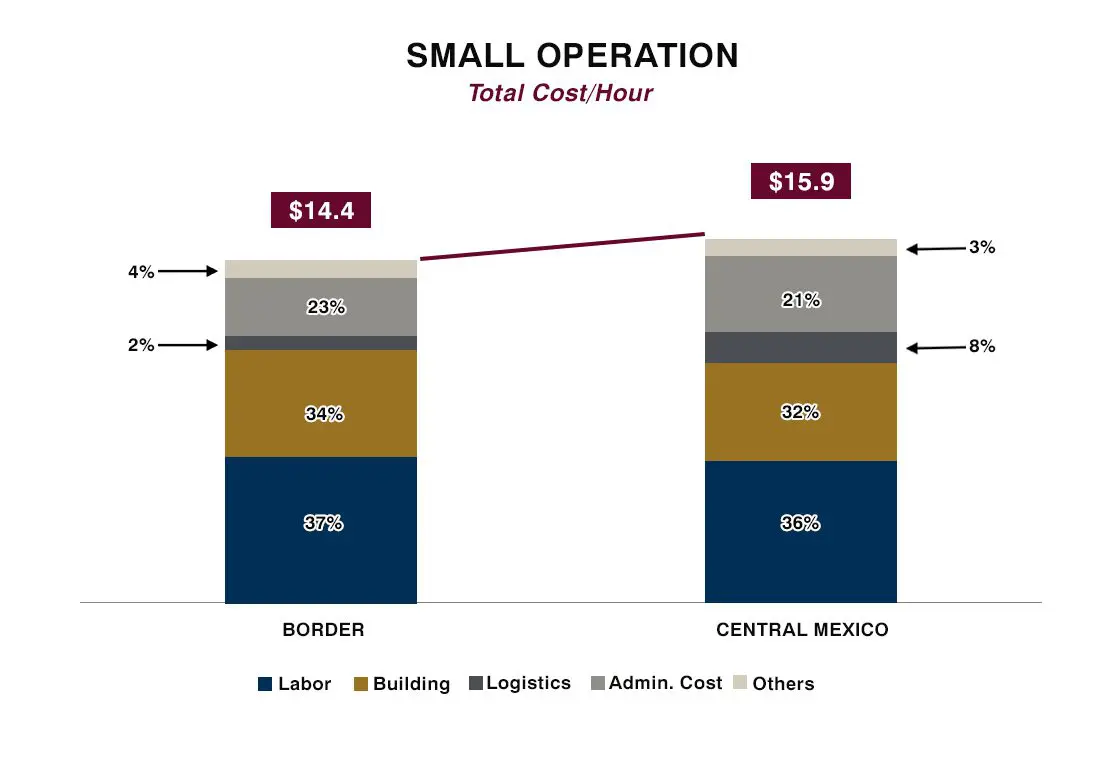

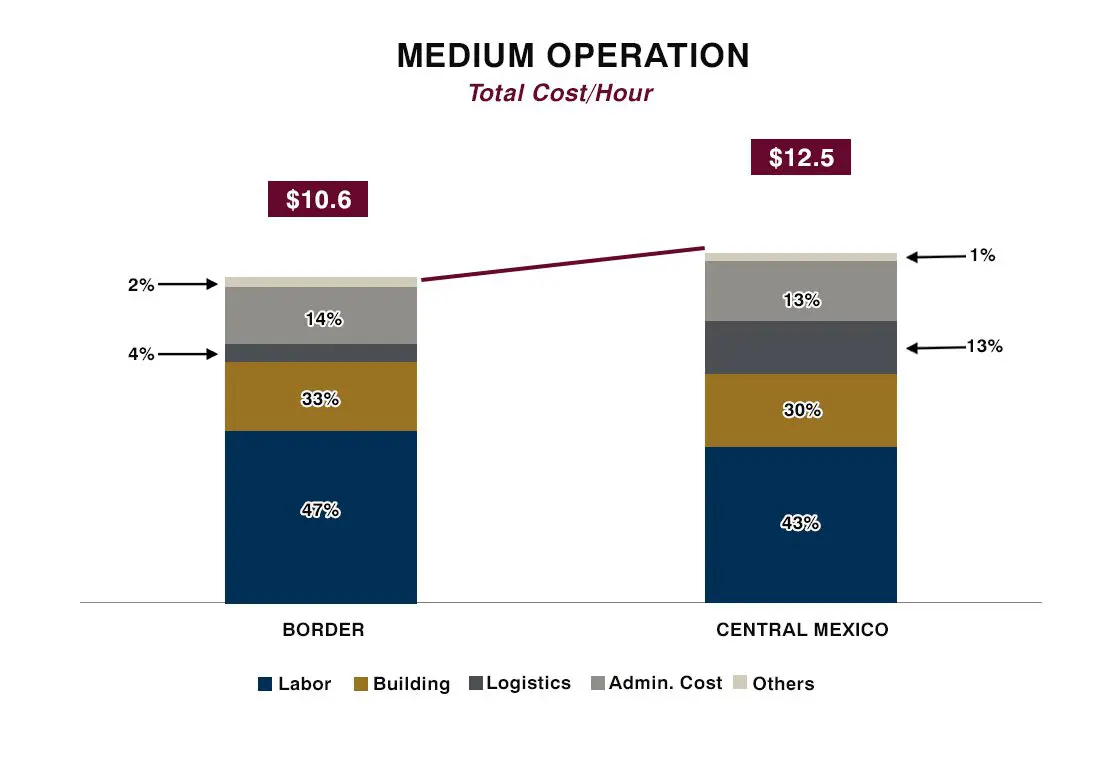

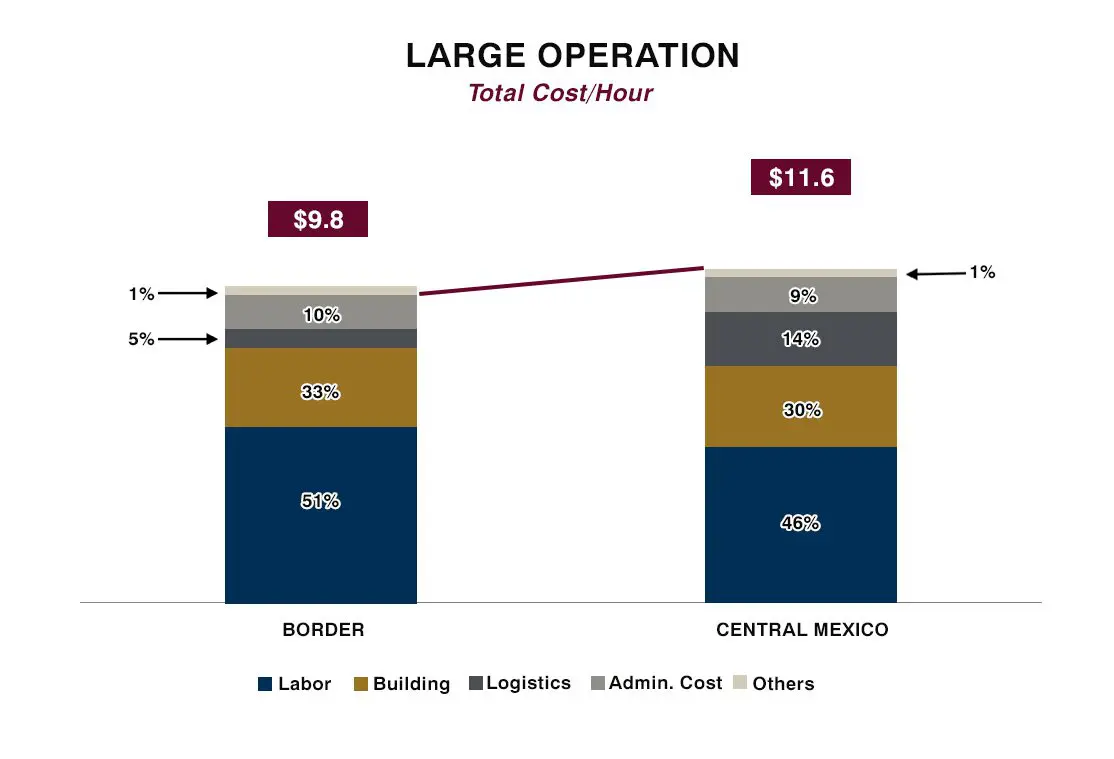

When considering starting up or relocating operations, including nearshore or offshore manufacturing in Mexico, one of the first steps is to have an estimated cost of your operation. In general, this cost can be divided into five main categories: labor, building, logistics, administrative costs, and others. Based on these, we have prepared some cost model simulations to get an estimated hourly operating cost for an industrial plant—both those located close to the border and in central Mexico. We have included a description of what each category entails, followed by graphics showing the total hourly rates and percentages allocated to each category, depending on the size of the operation and region.

The labor category considers salaries, benefits, and taxes delivering a fully loaded cost per hour. Though labor costs vary from one region to another, as do those for skilled and unskilled labor, our model considers direct, undirect, administrative and managerial positions in different regions as well as the benefits packages according to the specific labor market demands.

Then we have building costs. These include building rent, building NNN, park fees, building and process utilities, among others. When choosing a facility, a provider of shelter services in Mexico can help you find the building space that better fits your company’s specific needs, or if you wish to build, an industrial real estate developer can help you find a location and build a BTS facility as per your specific needs.

Next are logistics costs, which are key when estimating the total landed cost of importing and exporting goods from the border to the facility in Mexico and the other way around. These consider inbound / outbound and local freights, US and Mexican broker fees, freight forwarding, among others. The costs for logistics will vary based on the location, type of transportation among others such as insurance, security escort, etc.

Another critical category are administrative costs. These include services such as human resources, accounting and fiscal, customs coordination and duties optimization, legal compliance, EHS, purchasing of non productive goods, freight forwarding services, among others. The company providers of shelter services in Mexico, offer the above mentioned services and can help you to have a fast and smooth start up business in Mexico and a risk free operation, complying with all the rules and regulations of the law in Mexico.

The last category includes miscellaneous costs, such as security, cleaning, safety, office supplies, internet providers, and other support service suppliers.

The graphics below show the total estimated hourly costs in each region, considering the size of different operations.

For the small company simulations, it was considered the following data to calculate a cost per hour per month:

Headcount related: 50 employees / Facility related: 50,000 ft.2 / 4 inbound and 4 outbound shipments / Energy: 75,000 kwh / Water: 1,000 m3 / Nat. gas: 7,500 ft.3

for the medium one:

Headcount related: 150 employees / Facility related: 100,000 Sq.Ft. / 16 inbound and 16 outbound shipments / Energy: 150,000 kwh / Water: 5,000 m3 / Nat. gas: 15,000 ft.3

and for the large:

Headcount related: 300 employees / Facility related: 200,000 ft.2 / 32 inbound and 32 outbound shipments / Energy: 250,000 kwh / Water: 7,000 m3 / Nat. gas: 50,000 ft.3

With these kind of simulations, you can estimate the cost of your operation in Mexico in different regions of Mexico under different scenarios.

By Jorge Luis Baca | Queretaro Regional Director | American Industries Group®

Subscribe

US toll-free: +1 (877) 698 3905

CAN toll-free: +1 (844) 422 4922

start@americanindustriesgroup.com

Please note that we do not accept job applications here. If you are interested in applying for a position, please visit the following link: https://www.americanindustriesgroup.com/jobs/